Product Lifecycle Management (PLM) refers to the handling of a good as it moves through the typical stages of its product life: development and introduction, growth, maturity/stability, and decline. This handling involves both the manufacturing of the good and the marketing of it. The concept of product life cycle helps inform business decision-making, from pricing and promotion to expansion or cost-cutting.

Understanding Product Lifecycle Management (PLM)

Effective product life cycle management brings together the many companies, departments, and employees involved with the product’s production to streamline their activities, with the ultimate goal of producing a product that outperforms its competitors, is highly profitable, and lasts as long at consumer desire and technology permit. It goes well beyond just setting up a bill of materials.

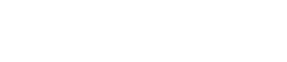

PLM systems help organizations cope with increasing complexity and engineering challenges of developing new products. They can be considered one of the four cornerstones of a manufacturing corporation’s information technology structure, the others being the management of communications with their clients (customer relationship management or CRM), their dealings with suppliers (supply chain management or SCM), and their resources within the enterprise (enterprise resource planning or ERP).

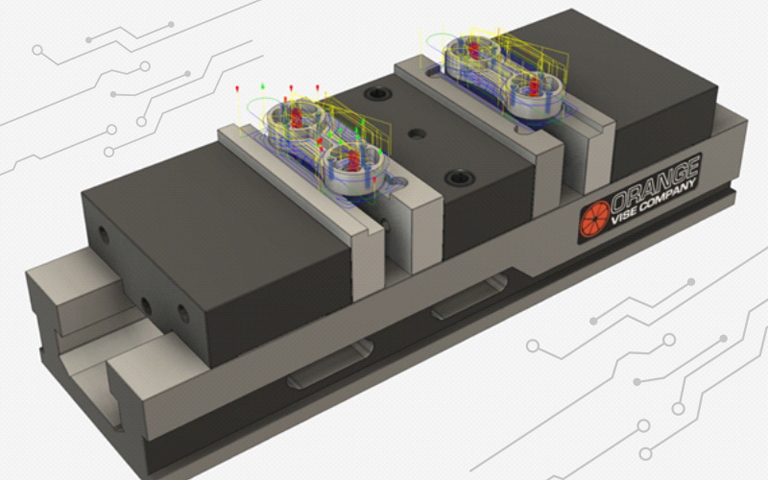

Once the model is prepared for machining, all information gets sent to a machine to produce the part physically. However, we can’t just give a machine a bunch of instructions in English. We need to speak the machine’s language. To do this, we convert all of our machining information to a language called G-code. This is the set of instructions that controls a machine’s actions, including speed, feed rate, coolants, etc.

Benefits of Product Lifecycle Management

- Improved product quality and reliability

- Reduced prototyping costs

- More accurate and timely requests for quote (RFQ) (solicitations from suppliers)

- Quick identification of sales opportunities and revenue contributions

- Savings through the re-use of original data

- A framework for product optimization

- Reduced waste

- Improved ability to better manage seasonal fluctuation management

- Improved forecasting to reduce material costs

- Maximized supply chain collaboration

A History of Product Lifecycle Management (PLM)

The concept of a product having stages of life (and the need to manage them) arose as early as 1931. Around 1957, an employee of Booz, Allen and Hamilton, the advertising agency, theorized a five-step life cycle for goods, beginning with the introduction phase, rising through growth and maturity, and eventually hitting saturation and decline.

Eventually, PLM developed as a manufacturing and marketing tool for businesses seeking to maximize the advantage of bringing new products to the market first.

One of the first recorded applications of modern PLM occurred with American Motors Corporation (AMC) in 1985. Looking for a way to speed up its product development process to better compete against its larger competitors in 1985—while lacking their larger budgets—AMC decided to place emphasis on bolstering the product lifecycle of its prime products (particularly Jeeps). Following that strategy, after introducing its compact Jeep Cherokee, the vehicle that launched the modern sport utility vehicle (SUV) market, AMC began development of a new model that eventually debuted as the Jeep Grand Cherokee.

Key Takeaways

- PLM refers to the handling of a good as it moves through the typical stages of its lifespan: development/introduction, growth, maturity, and decline

- PLM involves both the manufacturing of the good and the marketing of it.

- PLM’s main benefits include shortening product development times, knowing when to ramp up or reduce manufacturing efforts, and how to focus marketing efforts.